Ring Width 0.103 ID 0.487 Durometer A 70 Ethylene-Propylene

| 46-208640P7 | |

| X-Ray | |

| GE HealthCare | Outright |

Enter your approval number and submit to add item(s) to cart.

Please enter approval number

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without the

approval number, GE will contact you before your order

can be confirmed for shipment.

Select your approver's name and submit to add item(s) to your cart

Please Select Approver Name

OR

Don't know your approval number? Call 800-437-1171

Enter opt 1 for the first three prompts, and have your System ID available.

If you add item(s) to cart and submit your order without

selecting an approver, GE will contact you before your order

can be confirmed for shipment.

Features

- High rolling fatigue strength

- Free from corrosion

- Aesthetic in appearance

- Enhanced durability

Product Overview

The Ethylene Propylene Rubber (EPR) O-ring is used in X-Ray systems. Ethylene propylene rubber has high score impact strength. Generally O-ring is widely used as a leak source barrier. It is to be seated in a groove and compressed between two or more parts thereby creating a seal at the interface. Since there is no change of dimensions seen during an engagement in water or any deformation variations in solid material when the temperature increases, it has very high dimensional accuracy and stability. The ethylene propylene rubber material is resistant to ignition sources and has electrical insulation property. It involves an injection molding process, which is most reliable and efficient. The high dimensional accuracy ensures a perfect fit as per the requirement, also it is free from any burrs and sharp edges. The GE product is an innovation and technology which fits well into versatile customer needs. It is manufactured using high precision techniques which helps to achieve a good surface finish as well as good product consistency. The part is diligently designed for high performance and reliability. It is securely packaged inside a high quality packing box to avoid physical damage during transit and labeled with details about the product, Quality Assurance (QA) seal and shipment details.

Compatible Products

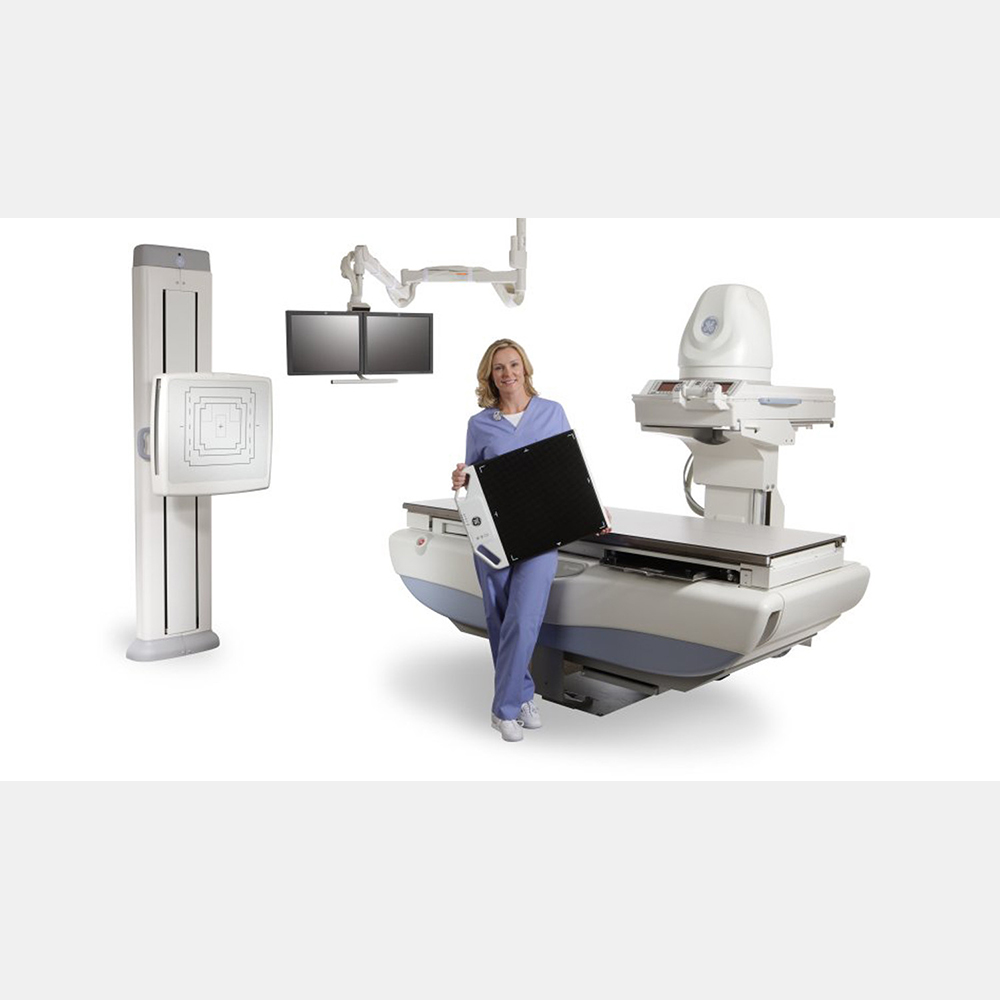

Precision 500D

Robust, digital performance at an efficient dose

It starts with the imaging chain, which features a 12-bit CCD-based camera.Then there’s AutoEx, which automatically adjusts key image-acquisition parameters in real time for optimum quality. Meanwhile, closed-loop Automatic Brightness Control and patented extended Dynamic Range circuitry maintain contrast and minimize blooming.